Our Products

Fuel Injection Pump Repair Kit Hydraulic Seal Kits Paper Gasket Copper Seal O-Rings Injector Washers

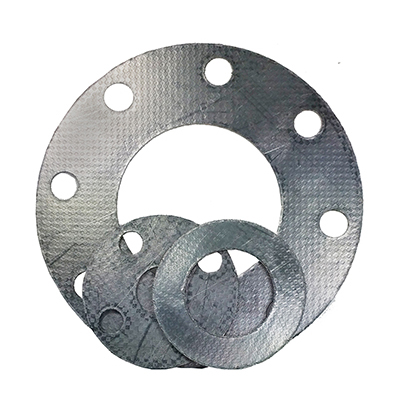

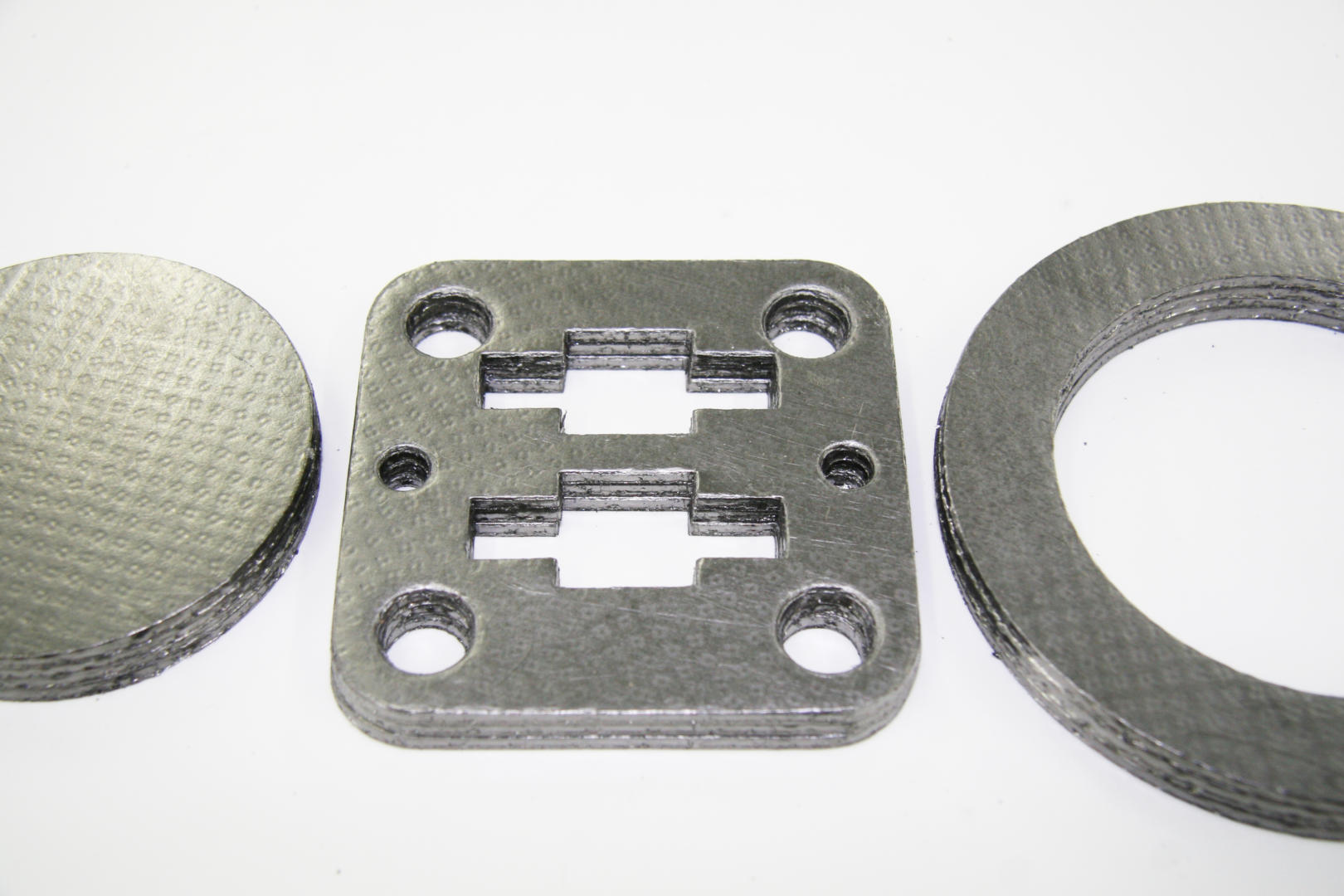

Graphite Gasket

Graphite gasket sheets are sheet-like materials made from compressed layers of high-purity graphite. They are used for creating gaskets in a wide range of industrial applications where sealing against fluid or gas leakage is essential. Graphite gasket sheets offer several advantages due to the unique properties of graphite:

1. Excellent Sealing Performance: Graphite gasket sheets provide excellent sealing performance, even in high-pressure and high-temperature environments. They are often used in applications involving steam, hot gases, and aggressive chemicals.

2. High-Temperature Resistance: Graphite gasket sheets can withstand extremely high temperatures, making them suitable for use in industries like petrochemical, chemical processing, and power generation, where elevated temperatures are common.

3. Chemical Resistance: Graphite is highly resistant to many chemicals and corrosive substances, which makes graphite gasket sheets ideal for sealing applications in harsh or corrosive environments.

4. Conformability: Graphite is a flexible material that can conform to irregular or uneven sealing surfaces, creating effective seals even on rough or non-uniform flange surfaces.

5. Low Emissions: Graphite gasket sheets are often used in applications where reducing emissions of volatile organic compounds (VOCs) or other harmful substances is crucial, such as in the chemical and petroleum industries.

6. Anti-Stick Properties: Graphite has a low coefficient of friction and anti-stick properties, which reduce the likelihood of gaskets sticking to mating surfaces after prolonged use.

Graphite gasket sheets are available in various grades and thicknesses to meet the specific requirements of different applications. They can be cut into the desired shapes and sizes to fit flanges, valves, pumps, and other equipment.

Common types of graphite gasket sheets include:

• Homogeneous Graphite Sheets: These sheets are made from pure graphite and are often used in applications with high temperatures and pressures.

• Reinforced Graphite Sheets: These sheets have a graphite core reinforced with metal foil or other materials, providing additional strength and stability. Reinforced sheets are used when increased mechanical strength is required.

• Laminated Graphite Sheets: These sheets consist of multiple layers of graphite with or without inserts of various materials. Laminated sheets are chosen based on the specific sealing requirements of an application.

Proper installation, torque procedures, and surface preparation are essential when using graphite gasket sheets to ensure effective sealing and prevent leakage. The selection of the appropriate sheet type and thickness depends on factors such as temperature, pressure, fluid compatibility, and flange conditions in the intended application.